Published in Surfaces and Interfaces: The role of alloying on texture evolution and solid-state dewetting of thin metallic films

The paper “Influence of Au alloying on solid state dewetting kinetics and texture evolution of Ag and Ni thin films” by Martin Dierner, Johannes Will, Michael Landes, Christian Volland, Robert Branscheid, Tobias Zech, Tobias Unruh and Erdmann Spiecker has just been published in the Journal of Surfaces and Interfaces. Congratulations Martin and colleagues!

Thin films are essential components in various technologies, from microelectronics to optics. However, their stability and structural integrity can be compromised by a phenomenon known as solid-state dewetting (SSD).

SSD occurs when a thin film undergoes spontaneous agglomeration at elevated temperatures, typically due to surface energy minimization. This process involves the formation of isolated islands or droplets, leading to the coalescence of neighboring film areas and the eventual breakdown of the film.

Understanding the mechanisms behind SSD is crucial for optimizing thin film manufacturing processes and enhancing the performance of devices. Factors such as film thickness, composition and substrate interaction play significant roles in governing the SSD behavior.

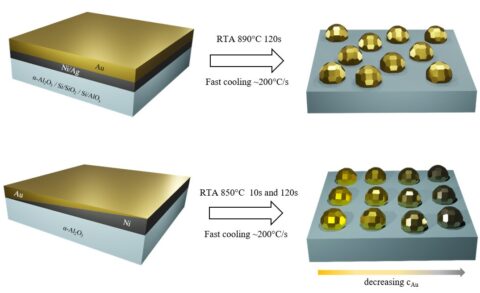

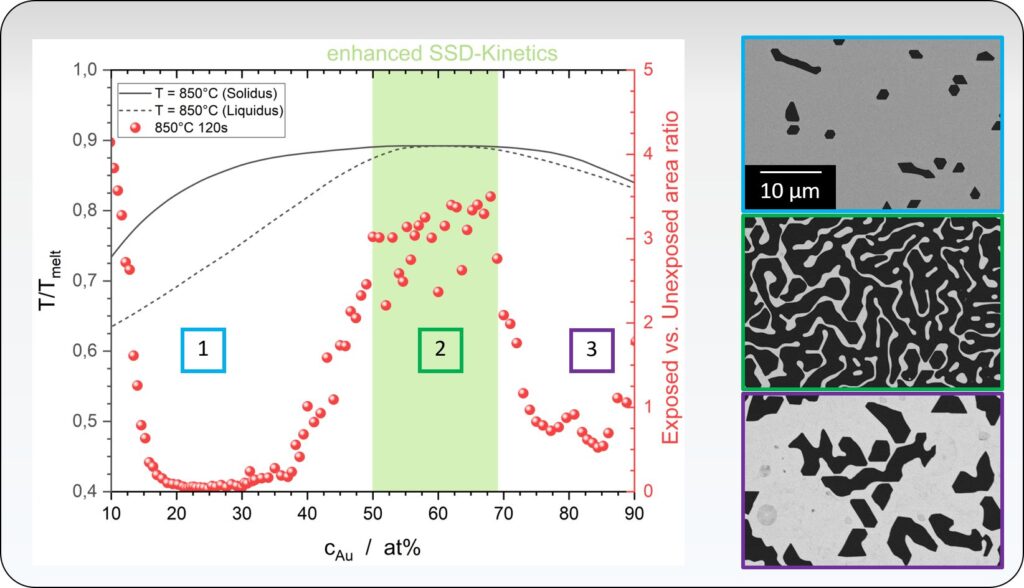

In the present work, we aim at a fundamental understanding of the role of alloying on the SSD kinetics and texture evolution of binary metallic alloy films by correlating X-ray diffraction and electron microscopy techniques. For that bilayers of a high (AuNi) and low (AuAg) atomic mismatch system are fabricated on different substrates and annealed utilizing a rapid thermal annealing furnace. A quantitative texture analysis yields that pure metal films (Ni, Au, Ag) exhibit the same degree of <111> texturing after SSD. In contrast, a reduced degree of texturing is observed for alloys as well as for pure Ni films on amorphous substrates. The texture loss is less pronounced for AuNi on sapphire which is likely due to in-plane texturing along densely packed directions stabilizing the <111> out-of-plane texture.

Regarding the thermal stability of alloy films, they found, that the SSD kinetics of the low-misfit AuAg system continuously changes with the Au concentration and can be perfectly described by composition dependent hole growth as reflected by the Mullins’ coefficient, while the high-misfit AuNi system resembles this behaviour only during early stages of SSD and shows a strong deviation of this behavior. The deviation from the Mullins coefficient indicates a shift in the prevailing mechanism, suggesting that this accelerated SSD occurs at compositions where the annealing temperature (T) approaches the melting temperature (Tm), i.e. liquidus line. Indeed, the reduced temperature (T/ Tm) exhibits its maximum within the compositional range where accelerated SSD is prominent.